How does the chemical resistance of CPVC pipe in industry affect its selection for applications in specific industries, such as chemicals or pharmaceuticals?

CPVC (Chlorinated Polyvinyl Chloride) is known for its excellent chemical resistance and is particularly suitable for industries such as chemical and pharmaceutical that handle corrosive fluids. This excellent performance makes CPVC pipes the choice for transporting strong acids, strong bases, organic solvents and other corrosive substances.

Application value in chemical industry

The chemical industry often needs to handle corrosive liquids or gases, such as sulfuric acid, sodium hydroxide, etc. Compared with metal pipes, CPVC has higher corrosion resistance and will not be oxidized or damaged due to long-term exposure to acidic or alkaline environments. This significantly reduces pipe maintenance costs and replacement frequency.

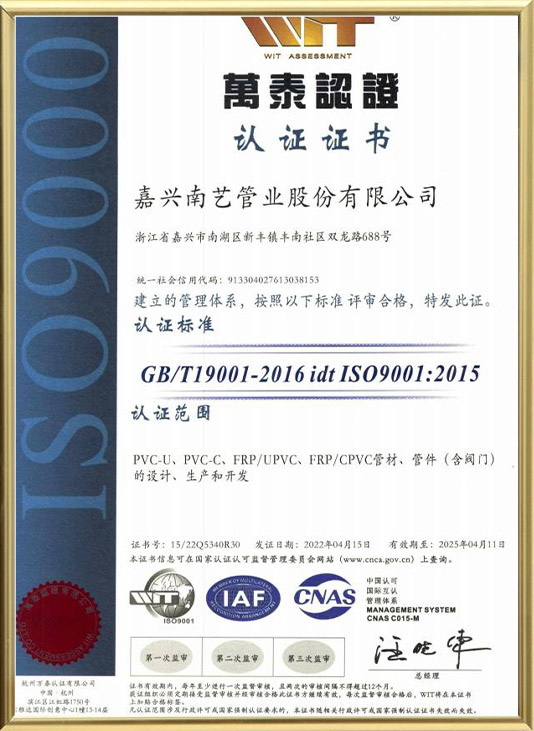

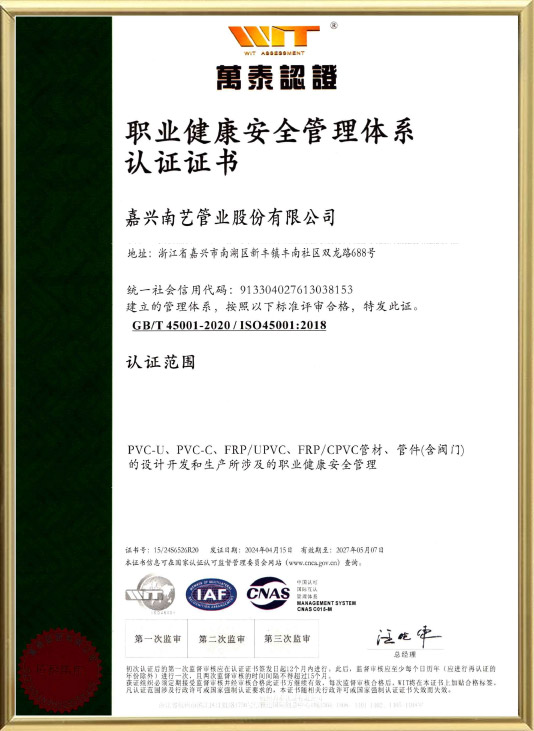

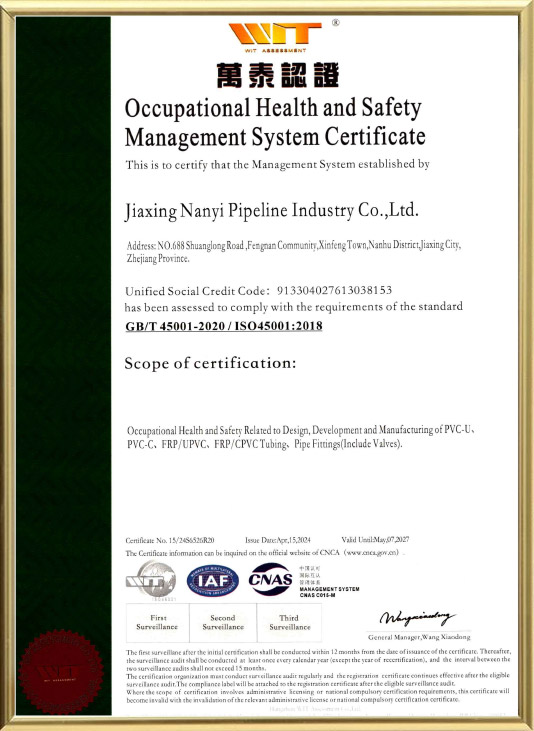

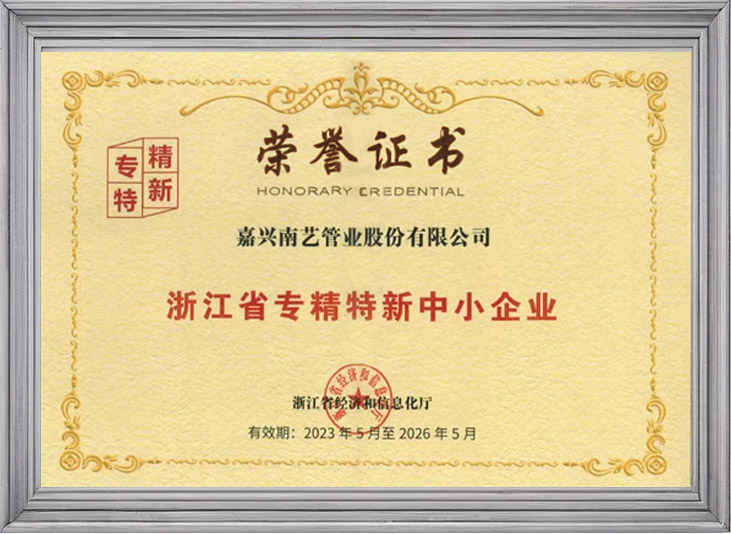

As a high-tech enterprise, ZHEYI Group relies on its complete production qualifications (such as special equipment production license and ISO certification system) to provide CPVC pipe products that meet high industry standards and provide stable and reliable transportation solutions for chemical companies.

Safety and Compliance in the Pharmaceutical Industry

The pharmaceutical industry has extremely high requirements on the hygienic performance of pipeline materials. Especially when transporting pure water, chemical reagents or pharmaceutical raw materials, pipelines must avoid contaminating the medium due to corrosion and release of harmful substances. CPVC's chemical inertness and high temperature resistance make it an ideal material for meeting GMP (Good Manufacturing Practice) requirements in the pharmaceutical industry.

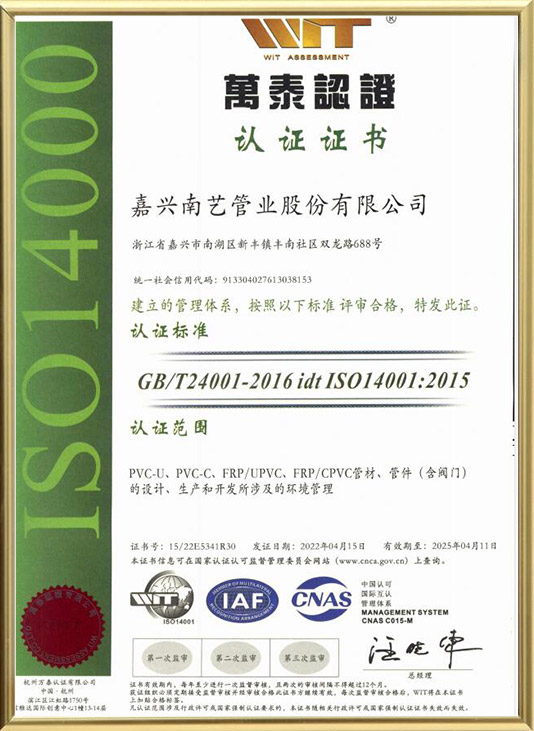

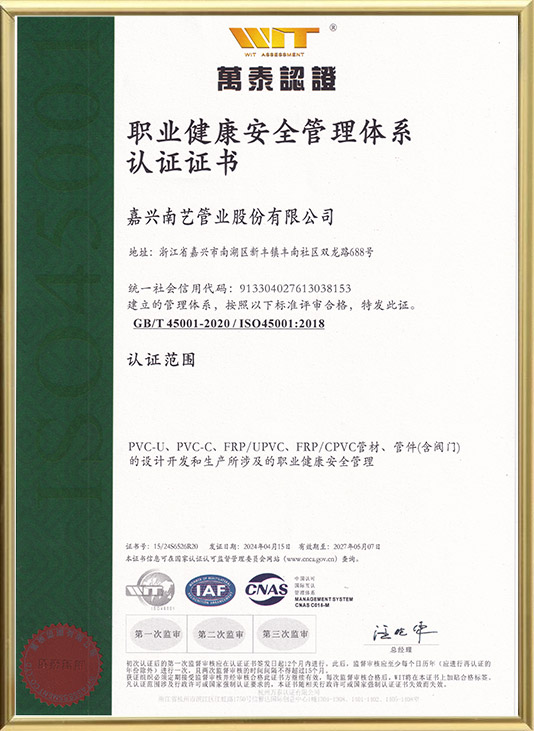

ZHEYI Group not only has a hygiene license for water-related products, but also passed the ISO14001 environmental management system certification, proving that its products focus on the environment and health. These qualifications provide the pharmaceutical industry with an additional layer of confidence.

Technological innovation and sustainable development

ZHEYI Group has more than 50 independent intellectual property rights and is able to develop and optimize the formula and production process of CPVC pipes to cope with more complex industrial needs. For example, improved temperature resistance and UV resistance allow the pipeline to maintain excellent performance in harsh environments. At the same time, CPVC pipes have a long service life, support recycling, and meet the requirements of modern industry for sustainable development.

Global service capabilities

Thanks to ZHEYI Group's independent import and export rights, its CPVC products not only serve the domestic market, but can also meet the needs of international customers. By providing high-performance CPVC pipes that meet international standards, ZHEYI occupies an important position in the global chemical and pharmaceutical market.

What are the unique requirements or advantages of welding and connecting processes for CPVC pipes in industrial installations?

Convenience and reliability of solvent welding

The most commonly used connection process for CPVC pipes is solvent welding, which uses solvents to soften the surface of the pipe to form a strong chemical bond. Compared with traditional materials (such as metal pipes that require complex welding techniques), solvent welding has lower technical requirements for operators, faster installation, and does not require additional heating equipment. This simple and efficient process has made ZHEYI Group's products widely used in a variety of industries (such as chemicals, nuclear power, and electronic semiconductors).

Special properties of high temperature resistance and chemical corrosion resistance

The advanced technology and raw materials introduced by ZHEYI Group from Germany and the United States give its CPVC pipes excellent performance. For example, during the welding or connection process, the use of imported high-quality raw materials can ensure that the weld remains stable under high temperature and acid-base environments. This advantage makes its products the first choice for transporting media such as acid-base liquids and electronic-grade water.

Modular design adapts to the needs of multiple industries

ZHEYI has a diverse range of products and can provide standardized or customized CPVC pipe systems according to different application scenarios. The connection design of these systems usually follows the modular concept, and the installation process is simplified through pre-designed pipe fittings and interfaces, making it more flexible and economical to use in industries such as photovoltaics, industrial water treatment, automobiles and food.

Leak-free connection improves safety

The unique advantage of CPVC pipe welding is that its welding point is integrated with the pipe itself to form a completely sealed connection. This is particularly critical in high-demand fields such as nuclear power and electronic semiconductors where ZHEYI products are widely used, which can effectively prevent medium leakage and ensure a safe operating environment.

+86-15258772971

+86-15258772971

dinys009@163.com

dinys009@163.com